In the realm of commercial roofing, finding reliable, energy-efficient, and durable insulation solutions is paramount. Cellular glass boards, composed of recycled glass, have emerged as a standout option due to their exceptional thermal insulation, moisture resistance, and fire safety properties. United Contracting & Roofing LLC, located in Greenville, SC, delves into the benefits and drawbacks of cellular glass boards to help you make an informed decision for your commercial roofing needs.

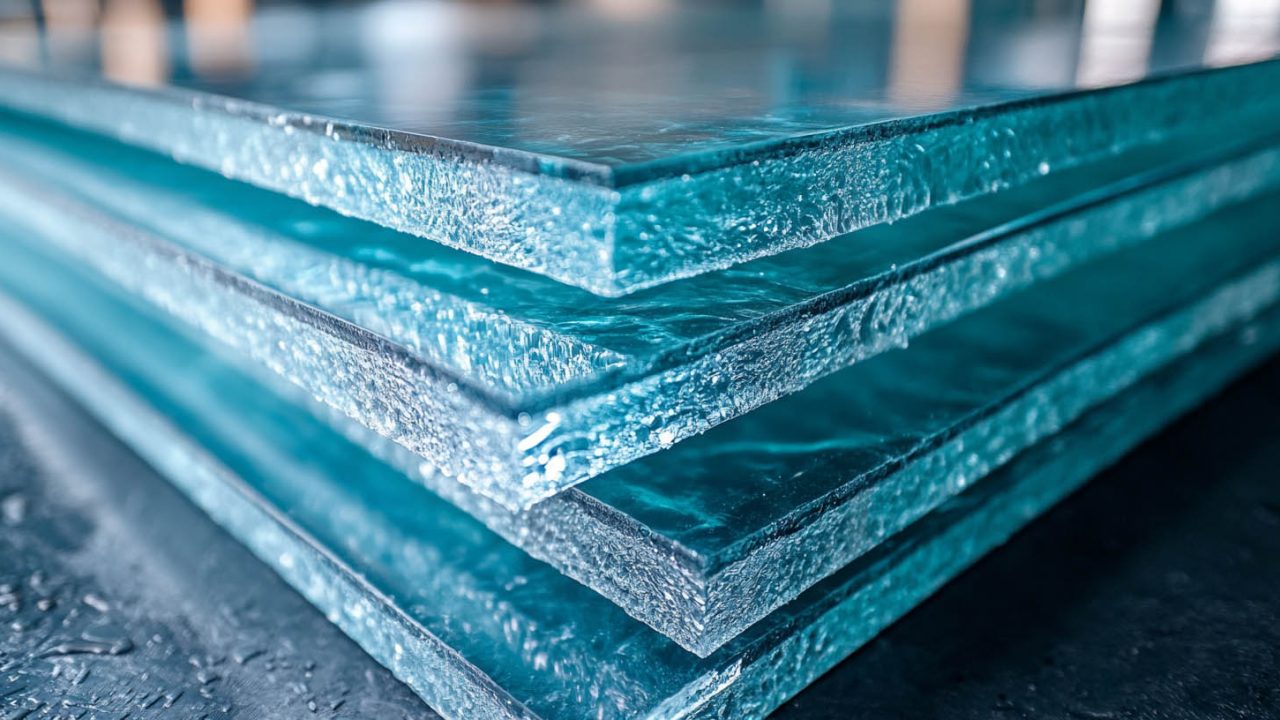

What Are Cellular Glass Boards?

Composition and Structure

Cellular glass board is a type of insulation material made from crushed glass combined with a foaming agent that creates numerous sealed air pockets. These air pockets make the material lightweight while providing excellent thermal insulation properties. The result is a durable, non-combustible, and moisture-resistant insulation board suitable for various roofing applications.

Applications

Cellular glass boards are commonly used in commercial roofing projects, particularly for flat roofs, green roofs, and other constructions where high-level insulation is required. Their environmental friendliness, owing to their recycled glass composition, makes them a popular choice for sustainable building practices.

Benefits of Cellular Glass Boards

Superior Insulation

Cellular glass boards offer high thermal insulation, helping maintain stable indoor temperatures. This efficiency can significantly reduce energy consumption and HVAC costs, making them a cost-effective choice in the long run.

Moisture Resistance

One of the standout features of cellular glass is its non-absorbent nature. This resistance to moisture prevents issues like mold growth and water damage, ensuring the longevity of the roofing system.

Fire Resistance

Being non-combustible, cellular glass boards enhance the fire safety of buildings. They resist flames and do not contribute to the spread of fire, making them an excellent choice for fire-prone areas.

Durability

Cellular glass boards have a long lifespan and are resistant to weathering, chemicals, and pests. This durability contributes to the overall longevity and reliability of the roofing system.

Load-Bearing Capacity

These boards can support heavy loads, making them suitable for roofs with foot traffic or equipment installations. This load-bearing capability adds to their versatility in commercial applications.

Environmental Friendliness

Made from recycled glass, cellular glass boards are eco-friendly. Their use promotes sustainable building practices and reduces the environmental impact of construction projects.

Ease of Installation

Cellular glass boards are relatively lightweight and easy to install, reducing labor time and costs. This ease of installation makes them a practical choice for many commercial roofing projects.

Drawbacks of Cellular Glass Boards

Higher Initial Cost

Cellular glass insulation can be more expensive upfront compared to some other insulation materials. This higher initial cost may be a consideration for budget-conscious projects.

Brittleness

The material can be brittle, making it susceptible to damage if mishandled during transportation, storage, or installation. Proper handling is essential to prevent breakage.

Limited Availability

Depending on the location, cellular glass boards might not be as widely available as other insulation materials. This limited availability could affect accessibility and procurement.

Installation Challenges

Specialized knowledge or techniques may be required for proper installation. Improper installation can compromise the effectiveness of the insulation, so it’s crucial to use experienced installers.

Rigid Structure

The rigidity of cellular glass boards might make them less suitable for curved or irregular surfaces, limiting their applicability in certain roofing designs.

Weight Considerations

While generally lightweight compared to some alternatives, cellular glass boards can still add some weight to the roofing structure, requiring careful consideration in load-bearing designs.

Thermal Expansion

In extreme temperature variations, cellular glass might experience minimal expansion and contraction. This thermal expansion could cause stress on the roofing system over time.

Cost of Cellular Glass Boards

Price Range

The cost of cellular glass boards typically ranges between $10 to $20 per square foot for materials only, though prices can fluctuate based on thickness, density, manufacturer, and location.

Factors Affecting Cost

- Thickness: Thicker boards generally cost more due to increased material usage.

- Density/Quality: Higher density or better quality boards might be more expensive but offer better insulation properties.

- Manufacturer and Brand: Prices can vary based on production processes, quality standards, and market positioning.

- Market Conditions: Regional demand, availability, and local market conditions can influence prices.

Additional Costs

Consider installation costs, transportation fees, taxes, and any additional materials or accessories needed when estimating the overall expense of using cellular glass boards in a roofing project. For accurate pricing, obtaining quotes from suppliers or manufacturers specific to your project’s requirements and location is recommended.

Conclusion

Cellular glass boards offer exceptional insulation, durability, and environmental benefits for commercial roofing applications. Despite higher initial costs and handling requirements, their long-term energy savings, moisture resistance, and fire safety make them a valuable investment. For more information on whether cellular glass boards are right for your commercial space, contact United Contracting & Roofing LLC.For more information on Four Tips for Fall Commercial Roof Maintenance, click here.